Sheeted Pellet Machine

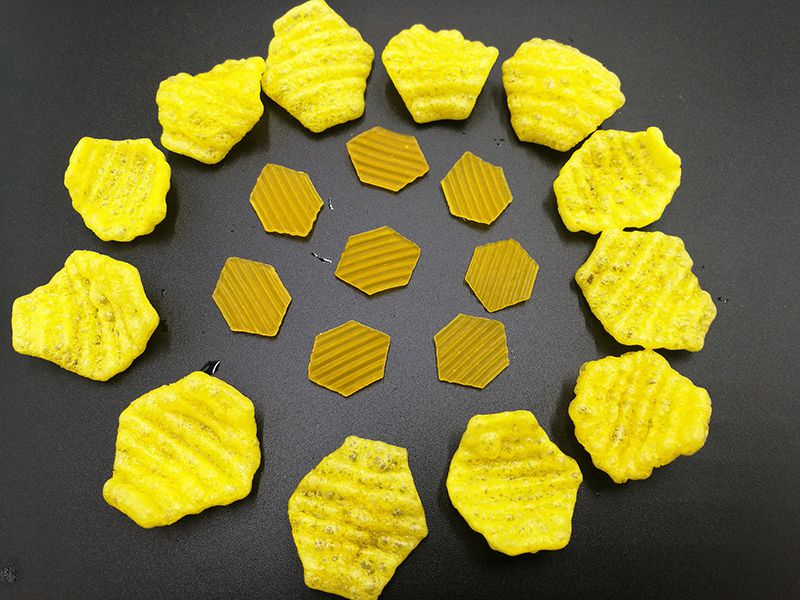

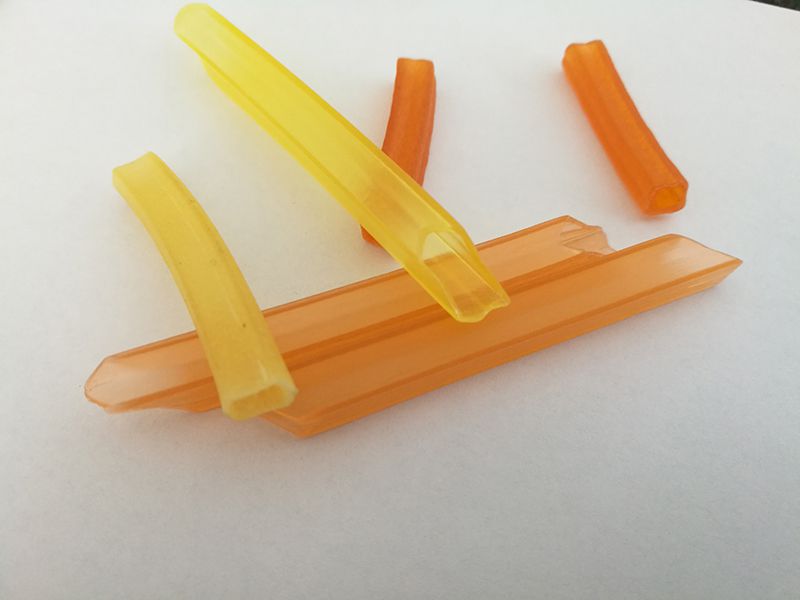

The sheeted pellet machine is designed for the production of semi-finished foods using potato starch, corn starch, tapioca starch, and flour. The single screw extruder is mainly used for the curing process. You can produce products in a variety of shapes by changing the mold. Combined with a fryer and sprayer, you can make delicious finished products. This production line features easy operation and maintenance as well as flexible combination, through which you can produce sheeted pellets, 3D pellets and shrimp chips, among many other popular snacks. We offer semi-automatic and fully automatic models.

Parameters

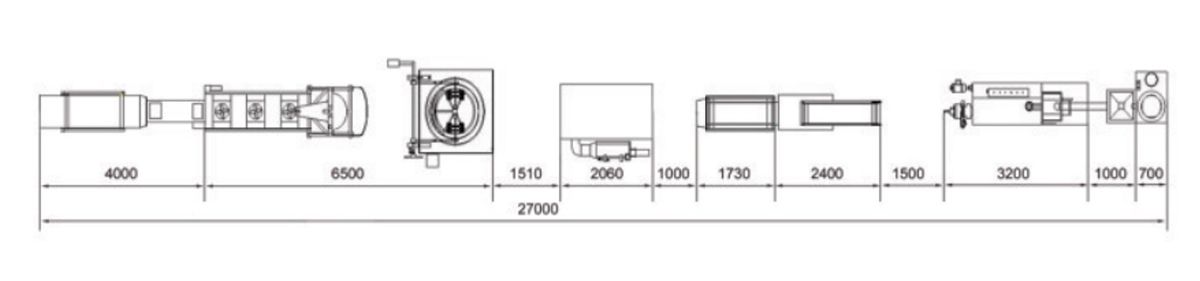

| Model | Installed Power | Power Consumption | Output | Size |

| FT63 | 142KW | 107KW | 150-200kg/h | 27000x2000x2000mm |

| FT75 | 178KW | 125KW | 250-300kg/h | 29000x2000x2000mm |

| FT95 | 278KW | 225KW | 400-600kg/h | 42000x2000x3200mm |

| LT100 | 117KW | 82KW | 80-100kg/h | 26000x2000x2000mm |

Flow Chart

Our Sheeted Pellet Machine is a food production line composed of the following components

- Flour Mixer

- Screw Conveyor

- Single Screw Extruder

- Drawing Machine

- Cooling Bed

- Drying Box

- Batch Fryer

- Seasoning Machine

Manufacture

Packaging

In addition to quality food equipment, we also offer complete customer services. For customers who have bought our food extruder, food mixer and fryers, etc. we provide food production formula, equipment installation and operator training, etc. We welcome you to contact us for more information!