Our Equipment

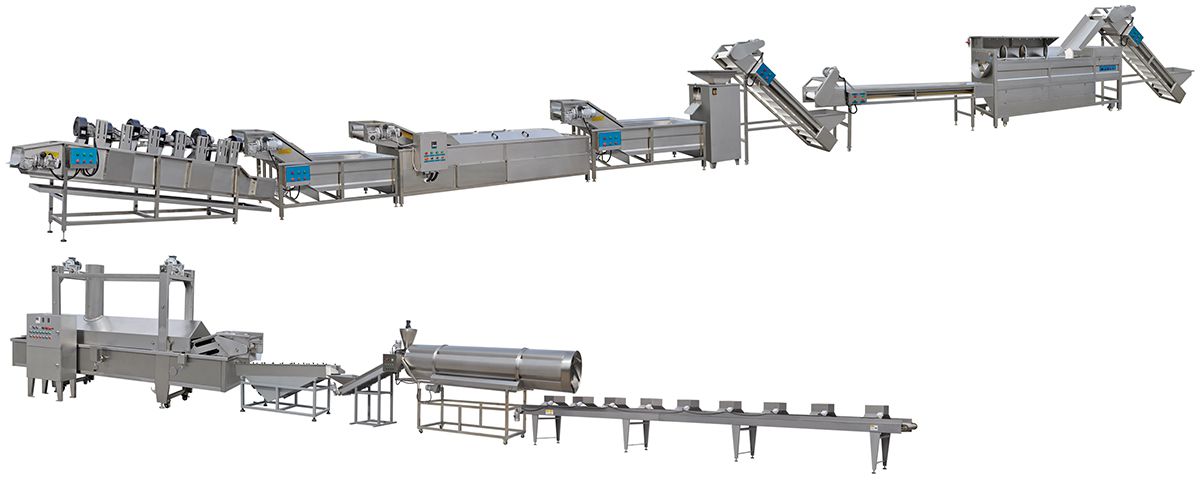

This fresh potato chips processing line was designed to address the needs of small-scale, low budget chip production operations. You can also customize your own model according to your operation’s individual needs.

After washing and peeling, potatoes are sliced evenly in the slicing machine. Potato chips are then rinsed and blanched to maintain their color. Excess water is removed from the chips before they enter the fryer. Finally, after de-oiling and seasoning, the finished products are packed in nitrogen filled bags.

Specifications

| Model | Capability | Power Consumption(electric and heating) | Power Consumption(gas, diesel and heat) | Workshop area needed |

|

LTSP-50 Simi-Automated Fresh Potato Chips Processing Line

|

50Kg/h | 78Kw | 15Kw | 150M2 |

|

LTSP-100 Fully Automated Fresh Potato Chips Processing Line

|

100Kg/h | 218Kw | 58Kw | 300M2 |

Process flow

Washing and peeling → slicing → rinsing → blanching → drying → frying and de-oiling → seasoning → packaging

Features

- China design compact and reasonable

- Easy operation and maintenance

- International brand electronics, big brand, reliable

- Equipped with an efficient and energy-saving combustion system, the heat source is distributed reasonably, the material is heated evenly, the energy consumption is low, and the output is large.

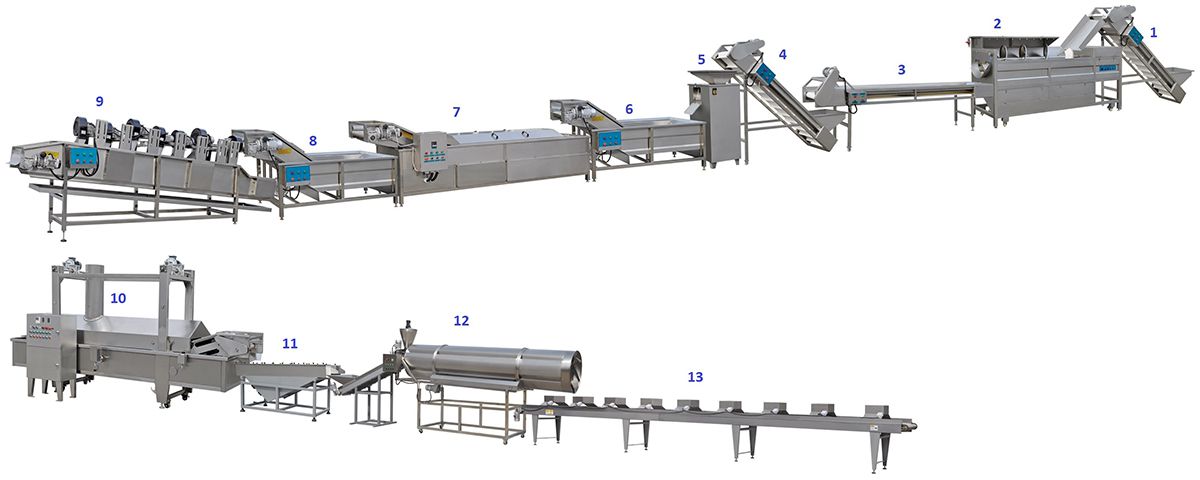

Flow Chart

- Raw Potato Conveyor

- Peeling Machine

- Selecting Conveyor

- Feeding Conveyor

- Slicing Machine

- Washing Machine

- Blanching Machine

- Washing Machine

- Cooling Machine

- Continuous Fryer

- Vibrant De-oiling Machine

- Single Drum Flavoring Machine

- Cooling Machine

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. LIGHT food processing machinery, animal food machinery, food extruders, etc. are used widely in the field of food processing, and we also provide customers with total food-production and processing solutions. We take pride in our ability to provide newer, better equipment to our customers to handle their ever changing needs.

Food Processing Line

Are you planning on making something tasty and visually attractive?

We can provide solutions tailored to your specific needs.

Contact Us