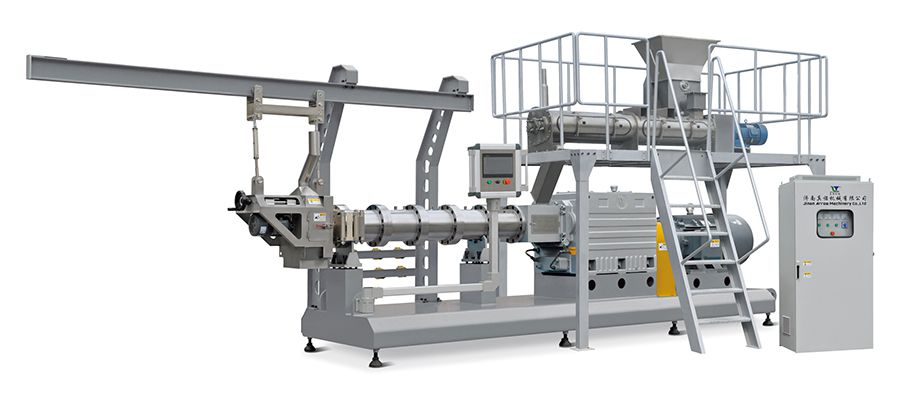

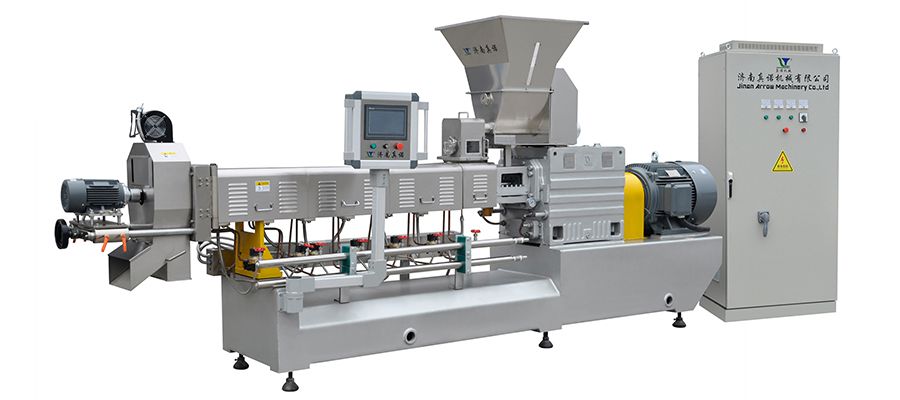

Multifunctional Twin Screw Extruder, ETT Series

Suitable for the production of puffed snacks, breakfast cereals, pet food and aqua feed

Main Features

- Screws can be freely arranged and combined to produce different products.

- Barrel liner is made of alloy, and it has long service life.

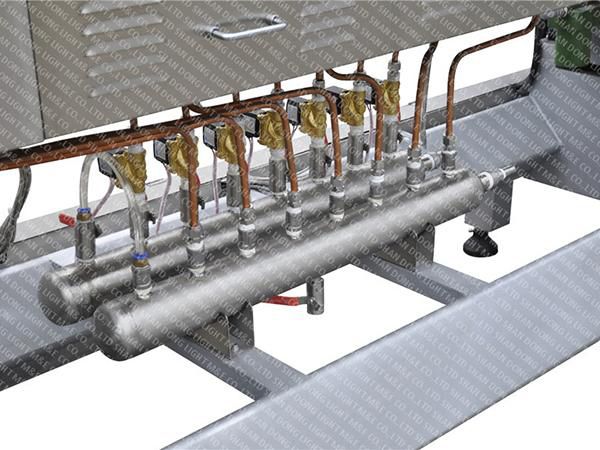

- There are various heating methods for customers' option. Multifunctional double screw extruder has low maintenance costs.

- The gear of multifunctional double screw extruder is processed sophisticatedly. The machine is assembled professionally. It is equipped with a distribution box of cooling, lubrication and filtration system.

- Multifunctional double screw extruder is controlled by touch screen. It can store the maximum of 24 sets of data.

- Electrical parts are supplied by foreign brands parts, such as Siemens, Omron, Fuji, Delta and LG.

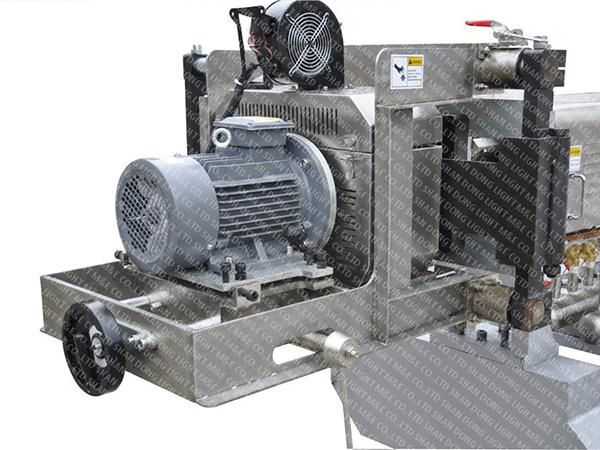

- Multifunctional double screw extruder features straight cutting. It is directly driven by the motor and the cutting force is strong.

Specifications

| Model | Main drive power | Output | Size(L×W×H) | Products |

| ETT36 | 11kW | 5-30kg/h | 3120*730*1900mm | Pellets, Puffs, Pet Food, Fish Feed, Corn Flakes, Breakfast Cereals, etc. |

| ETT65 | 55kW | 200-600kg/h | 4300*950*1800mm | |

| ETT78 | 75/90kW | 300-1000kg/h | 4700*1000*1700mm | |

| ETT98 | 200/250kW | 800-2500kg/h | 6500*1500*1800mm |

Details

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. LIGHT food processing machinery, animal food machinery, food extruders, etc. are used widely in the field of food processing, and we also provide customers with total food-production and processing solutions. We take pride in our ability to provide newer, better equipment to our customers to handle their ever changing needs.

Get in Touch