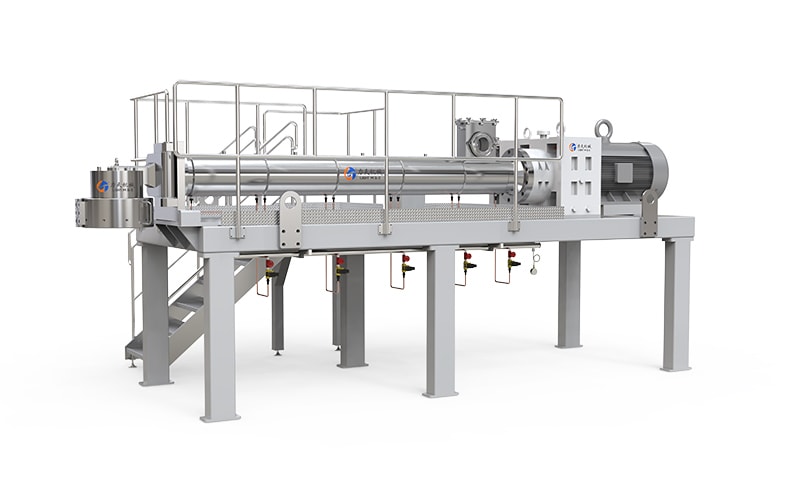

Single Screw Extruder, J Series

Suitable for the production of pellets and pet chews

Single Screw Extruder, J Series

Suitable for the production of pellets and pet chews

We are a major manufacturer of single screw extruder. This extruding equipment is ideal for using in food production line and feed production line. Due to reliable performance and competitive prices, our single screw extruder is popular with customers from Malaysia, Indonesia and Pakistan, to name a few.

Main Features

- The single screw extruder consists of feeding system, extrusion system, cutting system, heating system, lubricating system and cooling system.

- The material feeding system, main driving system and rotary cutting system are equipped with variable frequency speed adjustment system, which ensure reliable and steady operation of the extruder.

- The screw, barrel, and moulds are designed with cycle cooling system, ensuring a stable temperature during extrusion process.

- The screw is processed by our unique processing techniques, so it is abrasion resistant and has a long service life.

- In order to satisfy customers'different demands, the screw of the single screw extruder can be designed into different structures and with different length-to-diameter ratios.

Specifications

| Model | Main drive power | Output | Size(L×W×H) |

| J100 | 55kW | 30-100kg/h | 3255*955*1655mm |

| J130 | 55kW | 150-250kg/h | 4200*1000*1500mm |

| J150 | 55kW | 250-350kg/h | 5200*1200*2300mm |

| J180 | 75kW | 350-500kg/h | 4900*2000*2500mm |

| J200 | 110kW | 500-800kg/h | 6000*2000*2500mm |

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. LIGHT food processing machinery, animal food machinery, food extruders, etc. are used widely in the field of food processing, and we also provide customers with total food-production and processing solutions. We take pride in our ability to provide newer, better equipment to our customers to handle their ever changing needs.

Get in Touch